Our Articles

Stay up to date on the latest trends and best practices in the photonics industry.

Stay up to date on the latest trends and best practices in the photonics industry.

https://fisba.us/wp-content/uploads/2024/03/Experiment-in-photonic-laboratory-with-laser.jpg

1250

2000

Abstrakt MKTG

/wp-content/uploads/2023/09/logo-fisba-claim.svg

Abstrakt MKTG2024-03-21 10:29:382024-03-21 10:29:40Introduction to Optical Design and Engineering

https://fisba.us/wp-content/uploads/2024/03/Experiment-in-photonic-laboratory-with-laser.jpg

1250

2000

Abstrakt MKTG

/wp-content/uploads/2023/09/logo-fisba-claim.svg

Abstrakt MKTG2024-03-21 10:29:382024-03-21 10:29:40Introduction to Optical Design and Engineering https://fisba.us/wp-content/uploads/2023/12/Penny2.jpg

1198

1733

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

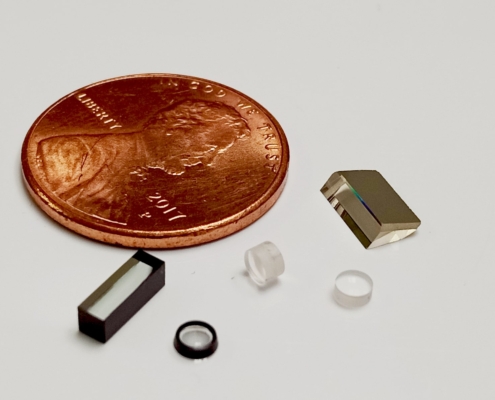

FISBA2022-10-14 09:14:002024-02-15 11:19:12Micro Optics

https://fisba.us/wp-content/uploads/2023/12/Penny2.jpg

1198

1733

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-10-14 09:14:002024-02-15 11:19:12Micro Optics https://fisba.us/wp-content/uploads/2023/09/Close-Up-of-Optical-Lens-in-Persons-Hand.jpg

1250

2000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-08-26 09:18:002024-02-15 11:19:13What is the Image Sensor Chief Ray Angle Spec

https://fisba.us/wp-content/uploads/2023/09/Close-Up-of-Optical-Lens-in-Persons-Hand.jpg

1250

2000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-08-26 09:18:002024-02-15 11:19:13What is the Image Sensor Chief Ray Angle Spec https://fisba.us/wp-content/uploads/2022/07/MTF.jpg

261

479

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-07-19 11:51:002024-03-26 11:23:16Resolution and MTF Testing

https://fisba.us/wp-content/uploads/2022/07/MTF.jpg

261

479

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-07-19 11:51:002024-03-26 11:23:16Resolution and MTF Testing https://fisba.us/wp-content/uploads/2023/12/addative-manufacturing.jpg

1260

1920

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-07-09 11:44:002024-03-26 08:59:40Complex Optics Prototypes Created With Additive Manufacturing From FISBA

https://fisba.us/wp-content/uploads/2023/12/addative-manufacturing.jpg

1260

1920

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-07-09 11:44:002024-03-26 08:59:40Complex Optics Prototypes Created With Additive Manufacturing From FISBA https://fisba.us/wp-content/uploads/2023/12/careers-culture.jpg

1200

1920

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-06-23 12:09:002024-03-26 11:23:32What Does an Optical Engineer Do?

https://fisba.us/wp-content/uploads/2023/12/careers-culture.jpg

1200

1920

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-06-23 12:09:002024-03-26 11:23:32What Does an Optical Engineer Do? https://fisba.us/wp-content/uploads/2023/12/cam2-min.jpg

1125

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-06-17 12:00:002024-03-26 11:23:48What Are Endoscopic Cameras?

https://fisba.us/wp-content/uploads/2023/12/cam2-min.jpg

1125

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2022-06-17 12:00:002024-03-26 11:23:48What Are Endoscopic Cameras?

https://fisba.us/wp-content/uploads/2023/12/Company-growth_COVID_v2.jpg

616

1313

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

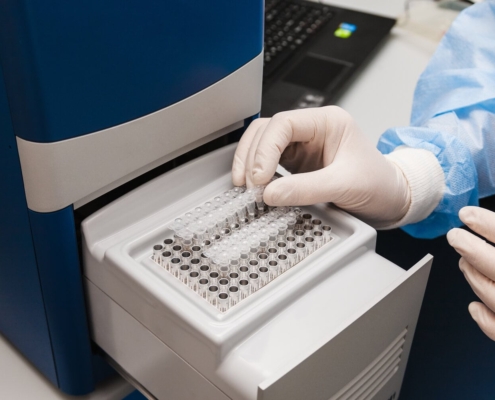

FISBA2020-11-17 11:40:002024-04-19 10:17:44Scaling Up to Quickly Advance COVID-19 Point-of-Care Testing Technologies

https://fisba.us/wp-content/uploads/2023/12/Company-growth_COVID_v2.jpg

616

1313

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-11-17 11:40:002024-04-19 10:17:44Scaling Up to Quickly Advance COVID-19 Point-of-Care Testing Technologies https://fisba.us/wp-content/uploads/2023/12/surgical-support-tool.png

616

1313

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-10-28 11:33:532024-02-15 11:20:40AR/VR As A Surgical Support Tool

https://fisba.us/wp-content/uploads/2023/12/surgical-support-tool.png

616

1313

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-10-28 11:33:532024-02-15 11:20:40AR/VR As A Surgical Support Tool https://fisba.us/wp-content/uploads/2023/09/FISBA-Optics-1.jpg

1250

2000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-07-29 11:27:002024-03-13 21:53:15Applications For Adaptive Optics In Ophthalmology, Surgery, And Dermatology

https://fisba.us/wp-content/uploads/2023/09/FISBA-Optics-1.jpg

1250

2000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-07-29 11:27:002024-03-13 21:53:15Applications For Adaptive Optics In Ophthalmology, Surgery, And Dermatology https://fisba.us/wp-content/uploads/2023/12/Image-quality-testing.jpg

721

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

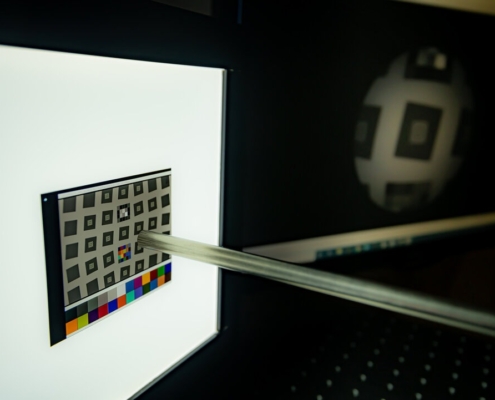

FISBA2020-06-18 11:21:002024-02-15 11:20:42Image Quality Testing For Medical Devices

https://fisba.us/wp-content/uploads/2023/12/Image-quality-testing.jpg

721

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-06-18 11:21:002024-02-15 11:20:42Image Quality Testing For Medical Devices https://fisba.us/wp-content/uploads/2023/12/coronavirus-detection.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-05-05 11:17:002024-02-15 11:20:42How Optics are Powering Coronavirus Detection and Diagnosis

https://fisba.us/wp-content/uploads/2023/12/coronavirus-detection.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-05-05 11:17:002024-02-15 11:20:42How Optics are Powering Coronavirus Detection and Diagnosis https://fisba.us/wp-content/uploads/2023/12/an-intraoral-camera-case-study.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-04-07 11:12:002024-02-15 11:20:43Bringing Complex Medical Imaging Devices to Market

https://fisba.us/wp-content/uploads/2023/12/an-intraoral-camera-case-study.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-04-07 11:12:002024-02-15 11:20:43Bringing Complex Medical Imaging Devices to Market https://fisba.us/wp-content/uploads/2023/12/metal-additive-manufacturing.jpg

667

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

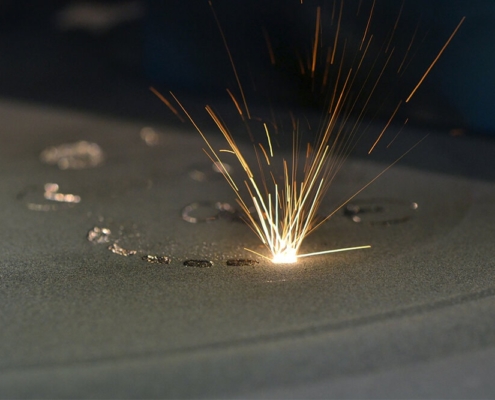

FISBA2020-03-24 09:56:002024-02-15 11:20:44Metal Additive Manufacturing & Optical Design

https://fisba.us/wp-content/uploads/2023/12/metal-additive-manufacturing.jpg

667

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-03-24 09:56:002024-02-15 11:20:44Metal Additive Manufacturing & Optical Design https://fisba.us/wp-content/uploads/2023/12/design-to-prototype-in-6-weeks.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-02-08 09:53:002024-02-15 11:20:44Design to Prototype in 6 Weeks

https://fisba.us/wp-content/uploads/2023/12/design-to-prototype-in-6-weeks.jpeg

1000

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-02-08 09:53:002024-02-15 11:20:44Design to Prototype in 6 Weeks https://fisba.us/wp-content/uploads/2023/12/athelas-case-study.jpg

742

1043

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-01-19 09:48:002024-02-15 11:20:45Is a Molded Glass Lens A Viable Option for Your Next Medical Device

https://fisba.us/wp-content/uploads/2023/12/athelas-case-study.jpg

742

1043

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2020-01-19 09:48:002024-02-15 11:20:45Is a Molded Glass Lens A Viable Option for Your Next Medical Device https://fisba.us/wp-content/uploads/2023/12/molded-glass-lens.jpg

320

427

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

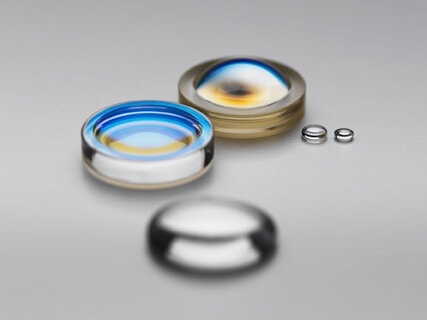

FISBA2019-11-05 09:45:002024-02-15 11:20:46Is a Molded Glass Lens A Viable Option for Your Next Medical Device

https://fisba.us/wp-content/uploads/2023/12/molded-glass-lens.jpg

320

427

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-11-05 09:45:002024-02-15 11:20:46Is a Molded Glass Lens A Viable Option for Your Next Medical Device https://fisba.us/wp-content/uploads/2023/12/cam2-min.jpg

1125

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-08-29 09:37:442024-02-15 11:20:47Bringing Complex Medical Imaging Devices to Market

https://fisba.us/wp-content/uploads/2023/12/cam2-min.jpg

1125

1500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-08-29 09:37:442024-02-15 11:20:47Bringing Complex Medical Imaging Devices to Market https://fisba.us/wp-content/uploads/2023/12/removing-uncertainty-in-your-design-process.jpg

333

500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-08-05 09:28:002024-03-26 08:49:10Removing Uncertainty in Your Design Process

https://fisba.us/wp-content/uploads/2023/12/removing-uncertainty-in-your-design-process.jpg

333

500

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-08-05 09:28:002024-03-26 08:49:10Removing Uncertainty in Your Design Process https://fisba.us/wp-content/uploads/2023/12/123RFLaparoscopicSurgery.jpg

666

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-07-12 09:25:002024-02-15 11:20:49An Innovation Path for Minimally Invasive Surgical Devices

https://fisba.us/wp-content/uploads/2023/12/123RFLaparoscopicSurgery.jpg

666

1000

FISBA

/wp-content/uploads/2023/09/logo-fisba-claim.svg

FISBA2019-07-12 09:25:002024-02-15 11:20:49An Innovation Path for Minimally Invasive Surgical DevicesThis site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds: